Table of Contents for Cordless Blinds (Spring Box and Motor) Selection Guide

Sep 17, 2025

Table of Contents for Cordless Blinds (Spring Box and Motor) Selection Guide

1. Introduction: Why Cordless Blinds Become the Preferred Choice for Home and Office Spaces

2. Selection Basics: Clarify Application Scenarios

3. Focus on Spring Box System: Matching Load-Bearing and Smooth Operation Requirements

4. Choose Motors Cautiously: Ensuring Convenient and Stable Control

5. Accurately Grasp Core Parameters: Ensuring Compatibility

6. Consider Installation and Maintenance: Reducing Long-Term Costs

7. Comply with Regulatory Standards: Avoiding Risks and Ensuring Safety

8. Innovative Functions of Cordless Blinds: Enhancing Performance and Service Life

9. Eco-Friendly Materials for Cordless Blinds: Balancing Safety and Sustainability

10. Common SEO-Optimized Questions about Cordless Blinds (Spring Box and Motor)

1. Introduction: Why Cordless Blinds Become the Preferred Choice for Home and Office Spaces

In modern home decoration and office space design, blinds, as important soft furnishings for adjusting light and protecting privacy, have been constantly evolving in form and function. Cordless blinds have gradually replaced traditional corded blinds and become the mainstream choice in the market, relying on two core advantages:

- Firstly, they have a neat and sleek appearance without messy cord tangles.

- Secondly, they offer significantly improved safety, making them especially suitable for families with children or pets and office spaces with high foot traffic, fundamentally eliminating the safety hazards caused by cord tangles.

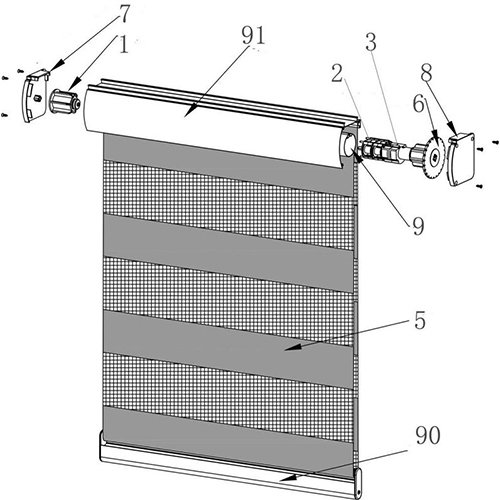

However, the user experience of cordless blinds is not determined by their appearance. Whether they can operate smoothly for a long time and how durable they are mainly depend on two key components: the spring box system and the motor.

The spring box serves as the "core framework" for the lifting function of cordless blinds, responsible for balancing the weight of the blind body and maintaining smooth lifting. The motor, on the other hand, acts as the "power heart," determining the convenience and stability of control. Many users tend to overlook the importance of these two components when purchasing, focusing only on the material or color of the blind slats. This ultimately leads to problems such as stuck lifting and frequent motor failures during use, which not only affect the user experience but also require additional maintenance costs.

Therefore, this guide will focus on the spring box system and the motor, providing a comprehensive and practical selection reference from the perspectives of application scenario analysis, component parameter comparison, avoidance of selection misunderstandings, cost calculation, and more.

2. Selection Basics: Clarify Application Scenarios

Before selecting the spring box and motor, the first step is to clarify the application scenario of the cordless blinds. Different scenarios vary greatly in terms of environmental humidity, usage frequency, and functional requirements, which directly determine the requirements for core parameters such as the load-bearing capacity of the spring box and the power of the motor. Skipping this step and making a blind selection may easily result in either "a small horse pulling a big cart" (insufficient capacity) or "excessive functionality," which either shortens the service life or increases unnecessary costs.

2.1 Component Adaptation Requirements for Different Scenarios

We will start with the two core scenarios of home and commercial use, and break down the specific requirements for spring boxes and motors in different sub-scenarios:

- Home Scenarios: Can be divided into bedrooms, living rooms, bathrooms, and kitchens. Bedrooms require a focus on "quietness" to avoid noise from lifting the blinds affecting rest. Therefore, the spring box should be a silent type, and the motor should preferably be a model with an operating noise of ≤35 decibels. The living room, as a high-frequency use area, usually has larger-sized blinds (e.g., 100-120cm in width), which need to be matched with a reinforced spring box and a medium-power DC motor. Bathrooms and kitchens have high humidity and are prone to oil stains, so the spring box must have anti-corrosion and waterproof properties (with a waterproof rating of at least IPX4), and the motor should be a model with an anti-corrosion shell to avoid short circuits due to moisture.

- Commercial Scenarios: Represented by offices, hotel rooms, and shopping mall display windows. Office blinds are used frequently (3-5 times a day for opening and closing), and some areas (such as meeting rooms) have requirements for quietness. It is recommended to choose a reinforced spring box with strong fatigue resistance (with a recommended maximum lifting frequency of ≥10,000 times) and an intelligent motor that supports scheduled adjustment or remote control. Hotel rooms need to balance durability and convenience; the spring box should be anti-corrosion (to cope with the humid environment during room cleaning), and the motor should be a low standby power consumption DC motor to avoid energy waste caused by long-term plugging. The blinds for shopping mall display windows are usually of extra-large size (width >150cm, height >250cm), and must be matched with a heavy-duty reinforced spring box with a load-bearing capacity of ≥12kg and an AC motor with a power of 15-20W to ensure that it can drive the large-weight blind body.

For a more intuitive understanding of the corresponding relationship between scenarios and components, you can refer to the adaptation logic of "Scenario - Spring Box Type - Motor Type". For example, "bedroom" corresponds to "silent spring box + DC silent motor", "hotel bathroom" corresponds to "anti-corrosion spring box + low-power DC motor", and "shopping mall display window" corresponds to "heavy-duty reinforced spring box + AC motor".

2.2 Impact of Blind Size and Weight on Selection (Taking Aluminum Blinds as an Example)

In addition to the scenario, the size and weight of the cordless blinds are another key basis for selection. The weight of the blind body varies significantly with different sizes. If the load-bearing capacity of the spring box is insufficient or the motor power is not enough, it will directly lead to difficulty in lifting. Conversely, using a high-load-bearing spring box with a small-sized blind body will result in excessive functionality and increased procurement costs. Below, taking the most common aluminum blinds on the market as an example, we will break down the component selection corresponding to different sizes:

2.2.1 Small-Sized Blinds: Width ≤60cm, Height ≤180cm, Weight 1.5-3kg

This type of blind is commonly used for small windows in homes (such as bay windows in bedrooms and small windows in kitchens) or partition windows in commercial spaces. The blind body is relatively light, so the requirements for the spring box and motor are low.

- Adaptable Spring Box: A regular type is sufficient, with a rated load-bearing capacity of ≤5kg (it is recommended to reserve 10%-20% redundancy for the actual load-bearing capacity to avoid accelerated fatigue due to long-term full-load operation). The advantages of regular spring boxes are low cost (unit price of approximately 30-50 yuan) and easy installation, without the need for complex fixed structures, making them suitable for quick installation by individuals or decorators.

- Adaptable Motor: Priority should be given to a DC motor with a power of 5-8W. DC motors are small in size and light in weight, and can be directly embedded in the cavity of the blinds without affecting the appearance. Moreover, they have low standby power consumption (<0.5W/h). If powered by AA batteries, a set of batteries can be used for 3-6 months without frequent replacement.

For example, if an aluminum blind with a width of 50cm and a height of 160cm (weight of approximately 2kg) is installed on a bedroom bay window, matched with a regular spring box (load-bearing 4kg) and a 6W DC motor, it can lift smoothly in daily use, and the noise is controlled at around 38 decibels, which will not affect sleep at all.

2.2.2 Medium-Sized Blinds: Width 60-120cm, Height 180-240cm, Weight 3-6kg

Medium-sized blinds are the mainstream choice for home living rooms and office workstations. The blind body has a moderate weight but is used frequently, so there are certain requirements for the durability of the components.

- Adaptable Spring Box: It needs to be upgraded to a "regular reinforced type" with a rated load-bearing capacity of ≤8kg. The internal spring of the reinforced spring box is made of high-strength manganese steel, and its fatigue resistance is 50% higher than that of the regular type. The recommended maximum lifting frequency can reach 8,000-10,000 times. Calculated based on 4 uses per day, it can be used stably for 5-6 years. In addition, the installation interface is more firm, which can avoid the problem of the spring box becoming loose after long-term use.

- Adaptable Motor: The motor power needs to be increased to 8-12W for a DC motor. For scenarios with high requirements for quietness (such as office meeting rooms), a "DC silent motor" can be selected. This type of motor has added sound insulation cotton inside, with an operating noise of ≤35 decibels. Even when adjusting the blinds during a quiet meeting, it will not interfere with the discussion. At the same time, it has a larger torque (≥0.5N·m), which can easily drive a 6kg blind body and avoid the situation of "getting stuck halfway during lifting".

Take an aluminum blind with a width of 100cm and a height of 220cm (weight of approximately 4.5kg) in the living room as an example. When matched with a reinforced spring box with a load-bearing capacity of 8kg and a 10W DC silent motor, almost no noise is heard during lifting, and the blind body does not slide down after being left standing for 24 hours, showing excellent stability.

2.2.3 Large-Sized Blinds: Width >120cm, Height >240cm, Weight >6kg

Large-sized blinds are mostly used in commercial spaces (such as shopping mall display windows and floor-to-ceiling windows in hotel lobbies) or large windows in villas. The blind body is heavy and installed at a high height, so there are high requirements for the load-bearing capacity and power of the components.

- Adaptable Spring Box: A "reinforced type" must be selected, with a rated load-bearing capacity of ≥12kg. This type of spring box has a more complex structure, and some models adopt a double-spring design, which can evenly distribute the weight of the blind body and avoid deformation caused by excessive force on a single spring. Meanwhile, the shell is made of thickened ABS plastic, which has strong impact resistance and can resist slight wind impact even when installed near windows on high floors.

- Adaptable Motor: DC motors can no longer meet the power requirements, so an AC motor with a power of 15-20W must be selected. AC motors rely on municipal power supply (220V), have stronger power and a torque of ≥1.0N·m, which can drive a blind body weighing more than 10kg. They also have good durability and will not trigger overheat protection even when running continuously for 1 hour, making them suitable for the frequent and long-term adjustment needs in commercial scenarios.

For example, if an aluminum blind with a width of 180cm and a height of 280cm (weight of approximately 9kg) is installed in a shopping mall display window, matched with a reinforced spring box with a load-bearing capacity of 15kg and an 18W AC motor, the lifting speed is stable (about 10cm/s), and there are no failures within one year of long-term daily use (6-8 times a day), which can fully meet the high-frequency use needs in commercial scenarios.

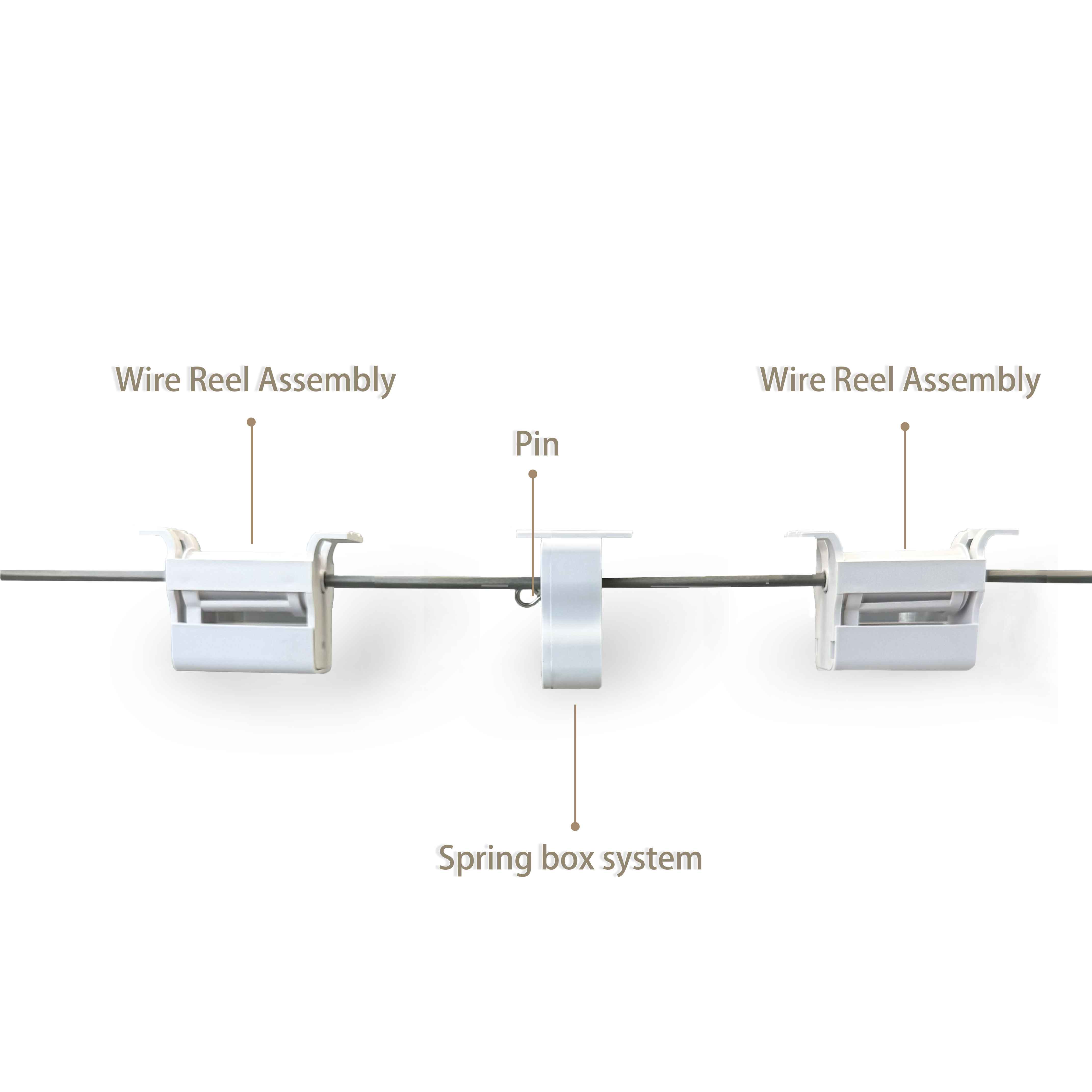

3. Focus on Spring Box System: Matching Load-Bearing and Smooth Operation Requirements

Although the spring box system is small in size, it is the "core support" for the lifting function of cordless blinds. Its role is not only to "hold" the weight of the blind body but also to ensure smooth lifting without jamming. At the same time, it can firmly fix the blind body in place when it stops, preventing it from sliding down. Therefore, selecting the correct type of spring box is the key to avoiding subsequent usage problems.

3.1 Mainstream Spring Box Types and Performance Parameters

Currently, spring boxes on the market are mainly divided into four types: regular type, reinforced type, silent type, and anti-corrosion type. They differ significantly in load-bearing capacity, fatigue resistance, and applicable scenarios. The specific parameters are shown in the table below:

Spring Box Type

Rated Load-Bearing Range

Recommended Maximum Lifting Times

Temperature Resistance Range

Core Advantages

Applicable Scenarios

Reference Unit Price (Yuan)

Regular Spring Box

3-5kg

≤5,000 times

-10℃-60℃

Low cost, easy installation

Small-sized cordless blinds for home use (e.g., small kitchen windows)

30-50

Reinforced Spring Box

8-12kg

10,000-15,000 times

-15℃-70℃

Strong load-bearing capacity, good fatigue resistance

Medium and large-sized commercial/home blinds (e.g., living rooms, offices)

80-120

Silent Spring Box

3-8kg

≤8,000 times

-10℃-60℃

Operating noise ≤35 decibels

Scenarios requiring quietness such as bedrooms and studies

60-90

Anti-Corrosion Spring Box

5-10kg

≤8,000 times

-15℃-75℃

Waterproof rating IPX4, rust resistance

Humid environments such as bathrooms and kitchens

90-130

It can be seen from the table that different types of spring boxes have their own focuses:

- If the budget is limited and the blind size is small, the regular spring box is a cost-effective choice.

- If the blind size is large and it is used frequently, the fatigue resistance advantage of the reinforced spring box can significantly extend its service life.

- If it is installed in a bedroom or study, the low-noise design of the silent spring box is crucial. It uses silent bearings inside, which greatly reduces the friction noise during lifting, even quieter than the sound of turning book pages.

- If it is used in a humid environment, the waterproof and rust-resistant properties of the anti-corrosion spring box are irreplaceable. The surface of its spring is coated with a double layer of galvanization and epoxy resin, which can prevent rust even in an environment with a humidity of more than 80% for a long time.

It should be specially noted here that when purchasing, attention must be paid to the "recommended maximum lifting times" and "temperature resistance range". The former is directly related to the service life. For example, a regular spring box has a lifting life of 5,000 times. If it is used 3 times a day, it can only be used for 4-5 years. However, a reinforced spring box with a lifting life of 15,000 times can be used for 13-14 years, showing a significant difference. The latter affects the stability in extreme environments. For example, in northern winters, the temperature near windows can drop to -15℃, and regular spring boxes may have stiff springs and stuck lifting, while reinforced or anti-corrosion spring boxes with a temperature resistance range covering -15℃ can operate normally.

3.2 Common Problems and Losses Caused by Wrong Spring Box Selection

Many users tend to "seek cheap prices" or "take it for granted" when purchasing, using the wrong type of spring box. This not only affects the use but also requires bearing additional maintenance costs. Below are two common misunderstandings and their consequences:

3.2.1 Using a Small Load-Bearing Spring Box with a Large-Sized Blind (e.g., Using a 5kg Load-Bearing Spring Box with an 8kg Blind)

This is the most typical misunderstanding of "a small horse pulling a big cart". Users may think that "as long as the spring box can hold the blind body, it's okay", but they ignore the damage to the spring caused by long-term full-load operation.

- Specific Consequences: When the spring is in an overloaded state for a long time, its fatigue speed will be 3-4 times faster than normal. Under normal circumstances, a regular 5kg spring box matched with a 3kg blind will not have obvious problems within 3 years. However, when matched with an 8kg blind, lifting jams will occur after only 3 months - the blind body "jerks" when descending and requires force to pull when ascending. Within 1 year, the spring will completely lose its elasticity, making the blind body unable to be fixed and sliding down when released. The spring box must then be replaced.

- Additional Cost Calculation: The cost of replacing a spring box once is approximately 80-150 yuan (if a reinforced spring box is selected, the cost is higher). Adding the on-site installation fee of 50-100 yuan, a single maintenance requires an expenditure of 130-250 yuan. If the replacement is not done in time, the blind body may be deformed due to long-term sliding, and the entire blind will need to be replaced later, resulting in greater losses (the unit price of blinds is usually 300-800 yuan).

A family user once matched a 5kg regular spring box with a 7kg blind (120cm in width) for the living room. As a result, jams occurred after only 4 months. During maintenance, not only did they spend 120 yuan to replace it with a reinforced spring box, but also 2 slats were deformed due to the long-term sliding of the blind body, requiring an additional 60 yuan to replace the slats. The total loss was far more than the 50 yuan difference in the spring box price they "saved" initially.

3.2.2 Using a Regular Spring Box in a Humid Bathroom Environment

The bathroom is the area with the highest humidity in the home (humidity can reach more than 90% when taking a shower). Regular spring boxes (regular type and reinforced type) have poor waterproof performance, and direct use will easily lead to rusting.

- Specific Consequences: The springs of regular spring boxes are mostly exposed or only undergo simple galvanization. In a high-humidity environment, obvious rust will appear within 6 months - reddish-brown rust stains will appear on the spring surface, and the friction resistance during lifting will increase, eventually causing it to get completely stuck and unable to lift. At this time, not only the spring box needs to be replaced, but also the rust residue in the blind track needs to be cleaned, otherwise, it will affect the operation of the new spring box.

- Loss Calculation: The cost of the initially purchased regular spring box is approximately 50-80 yuan. After it becomes unusable due to rust, it is necessary to replace it with an anti-corrosion spring box (unit price of 90-130 yuan). Adding the labor cost for cleaning and installation of 80-120 yuan, the total loss is approximately 220-330 yuan. What's more troublesome is that the blind cannot be used during maintenance, which affects the privacy protection of the bathroom. It will be very inconvenient if there are guests at home.

A hotel once purchased a large number of cordless blinds with regular spring boxes for the bathroom in guest rooms. As a result, nearly 80% of the spring boxes rusted after 6 months. Not only did they spend more than 20,000 yuan to replace them with anti-corrosion spring boxes in bulk, but also some guest rooms could not be occupied due to maintenance, resulting in a loss of nearly 10,000 yuan in room revenue. This is a painful lesson.

4. Choose Motors Cautiously: Ensuring Convenient and Stable Control

If the spring box is the "framework" of the cordless blind, then the motor is the "heart". The power, noise, and control method of the motor directly determine the convenience of control and the user experience. Especially with the popularization of smart homes, more and more users choose cordless blinds with motors. If the motor is not selected properly, problems such as "stuck control", "high energy consumption", and "disturbing noise" are likely to occur.

4.1 Mainstream Motor Types and Performance Comparison

Currently, motors for cordless blinds on the market are mainly divided into four types: DC motors, AC motors, silent motors, and intelligent motors. They differ significantly in core parameters such as power, power consumption, and noise, and are suitable for different scenarios. The specific comparison is as follows:

Motor Type

Power Range

Standby Power Consumption

Operating Noise

Control Method

Power Supply Method

Applicable Scenarios

Reference Unit Price (Yuan)

DC Motor

5-12W

<0.5 W/h

≤40 decibels

Manual button, basic remote control

Battery (AA/lithium battery), low-voltage power supply

Small and medium-sized home blinds (e.g., bedrooms, kitchens)

80-150

AC Motor

15-25W

<1 W/h

≤45 decibels

Button, remote control

Municipal power supply (220V)

Large-sized, high-frequency use commercial blinds (e.g., shopping mall display windows, offices)

180-250

Silent Motor

8-15W

<0.5 W/h

≤30 decibels

Button, APP, voice (smart version)

Battery, low-voltage power supply

Quiet scenarios such as bedrooms and offices

150-220

Intelligent Motor

10-20W

<1 W/h

≤35 decibels

APP, voice, timing, smart home linkage

Battery, low-voltage power supply

Home/commercial scenarios pursuing convenient control (e.g., young families, smart offices)

200-300

5. Accurately Grasp Core Parameters: Ensuring Compatibility

After selecting the correct types of the spring box and motor, it is necessary to further check the core parameters to ensure that both are fully compatible with the size and weight of the blind. Even if the types are correct, if the parameters are not compatible (e.g., the load-bearing capacity of the spring box is exactly equal to the weight of the blind body, or the motor power is slightly lower than required), operational problems may still occur. Below, taking a "medium-sized aluminum blind with a width of 90cm, height of 200cm, and weight of 4.5kg" as an example, we will break down the compatibility logic of the core parameters.

Component Type

Core Parameter Requirements

Recommended Specification Example

Compatibility Verification Standard

Spring Box

Load-bearing capacity ≥4.5kg, temperature resistance -10℃-60℃

Reinforced spring box (load-bearing 8kg)

No jamming during 10 lifting cycles, no sliding of the blind body after 24 hours of standing

Motor

Power ≥10W, torque ≥0.5N·m

DC silent motor (10W, 0.6N·m)

Noise ≤35 decibels during full-load operation

Installation Compatibility

Spring box interface matches the track, motor size is compatible with the blind cavity

Spring box interface Φ15mm, motor size 100×50×30mm

No forced splicing after installation, no component extrusion

5.1 Detailed Explanation of Core Parameters

5.1.1 Core Parameters of the Spring Box: Load-Bearing Capacity and Temperature Resistance

- Load-Bearing Capacity: It must meet the requirement that "the load-bearing capacity ≥ the weight of the blind body", and it is recommended to reserve 30%-50% redundancy. For example, if the blind body weighs 4.5kg, it is recommended to select a reinforced spring box with a load-bearing capacity of 8kg, with a redundancy of 78%, to avoid spring fatigue caused by long-term full-load operation. If only a spring box with a load-bearing capacity of 5kg is selected, although it can barely support the blind body, the redundancy is only 11%, and lifting jams may occur within 3-6 months.

- Temperature Resistance Range: It needs to cover the extreme temperature of the installation environment. If installed near a bedroom window in the north, the temperature may drop to -10℃ in winter, so the temperature resistance range of the spring box must include -10℃. If installed on a balcony in the south, the temperature may reach 55℃ after exposure to the sun in summer, so the upper limit of temperature resistance must be ≥60℃ to prevent the spring from becoming soft and losing elasticity due to high temperatures.

5.1.2 Core Parameters of the Motor: Power and Torque

- Power: It needs to be matched according to the weight of the blind body. Generally, "2-3W of power is required per kilogram of the blind body". A 4.5kg blind body requires a power of ≥4.5×2=9W, so a 10W motor is recommended. The power is slightly higher than required to ensure sufficient lifting power. If an 8W motor is selected, although it can drive the blind body, it may trigger overheat protection due to insufficient power during long-term use, shortening its service life.

- Torque: Torque is the "rotational force" of the motor to drive the blind body, with the unit of N·m (Newton-meter). The heavier the blind body, the greater the required torque. Generally, "0.1-0.15N·m of torque is required per kilogram of the blind body". A 4.5kg blind body requires a torque of ≥4.5×0.1=0.45N·m, so a 0.6N·m motor is recommended to ensure that there is no "jamming" during lifting.

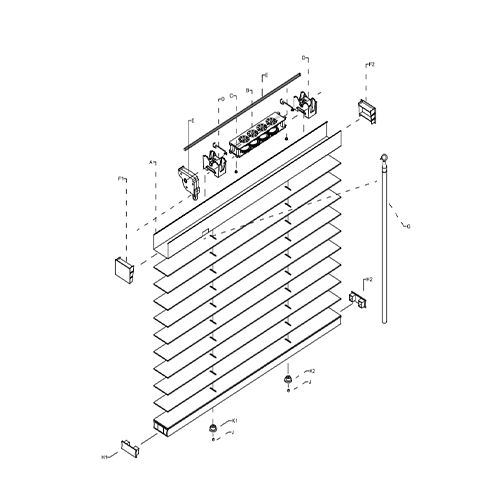

5.1.3 Installation Compatibility Parameters: Interface and Size

- Spring Box Interface: It needs to be consistent with the interface size of the blind track. Currently, the mainstream interface diameters on the market are Φ15mm or Φ18mm. When purchasing, it is necessary to measure the interface size of the track to avoid the problem that "the spring box cannot be installed into the track". For example, if the track interface is Φ15mm, a spring box with an interface of Φ15mm should be selected. If a spring box with an interface of Φ18mm is mistakenly selected, forced installation will cause deformation of the track.

- Motor Size: It needs to be compatible with the cavity size of the blind. The blind cavity is usually a rectangular space with "length × width × height". When purchasing a motor, it is necessary to ensure that the motor size is at least 5mm smaller than the cavity size to prevent the motor from being unable to be embedded or squeezing the cavity after embedding, which affects the normal folding of the blind. For example, if the cavity size is 110×55×35mm, a motor of 100×50×30mm is recommended to reserve sufficient space.

5.2 The Importance of Compatibility Verification

After matching the parameters, it is necessary to conduct compatibility verification before installation to avoid problems caused by parameter labeling errors:

- Spring Box Verification: After assembling the spring box with the blind body, manually lift it 10 times to check for jamming or abnormal noise. After lifting it to the middle position, let it stand for 24 hours and check if the blind body slides down (under normal circumstances, the sliding amount should be ≤2cm).

- Motor Verification: After powering on the motor, drive the blind body to run at full load (i.e., lifting when the blind body is fully unfolded). Use a sound level meter to measure the operating noise and ensure it is ≤35 decibels. At the same time, observe whether the lifting speed is uniform to avoid the unstable situation of "fast-slow-fast".

6. Consider Installation and Maintenance: Reducing Long-Term Costs

Many users think that "selecting the correct components is everything", but they ignore the impact of installation methods and later maintenance on long-term costs. Different installation methods vary greatly in maintenance difficulty, cycle, and cost. In addition, the timeliness of spare parts supply will also affect the maintenance downtime. Especially in commercial scenarios, the longer the downtime, the greater the loss.

6.1 Comparison of Maintenance Costs and Cycles for Different Installation Methods

There are mainly three installation methods for cordless blinds: external mounting, embedded mounting, and integrated mounting. They differ significantly in maintenance costs and cycles:

Installation Method

Initial Installation Difficulty

Single Maintenance Time

Recommended Maintenance Cycle

Single Maintenance Cost (Including Accessories)

Core Advantages

Applicable Scenarios

External Mounting

Low (no drilling required)

10-15 minutes

Once every 6 months

30-80 yuan

Convenient maintenance, suitable for rental scenarios

Rental houses, temporary office spaces

Embedded Mounting

Medium (cavity reservation required)

20-30 minutes

Once every 12 months

50-120 yuan

Neat appearance, suitable for fixed decoration

Permanent family residences, hotel rooms

Integrated Mounting

High (needs to be linked with the ceiling)

40-60 minutes

Once every 18 months

100-200 yuan

Seamless integration with interior design

Villas, high-end offices

6.1.3 Integrated Mounting: Aesthetics First, Suitable for High-End Scenarios

Integrated mounting requires the blind to be fully integrated with the ceiling and walls. For example, the blind track is embedded inside the ceiling, with only the slats exposed, achieving a seamless visual connection with the ceiling and the highest level of aesthetics.

- Maintenance Difficulty: During maintenance, part of the ceiling must be removed to take out the blind. A single maintenance takes 40-60 minutes and requires professional operation to avoid damaging the ceiling structure.

- Maintenance Cost: The labor cost is high (100-150 yuan). Adding the cost of accessories, the single maintenance cost is 100-200 yuan, which is the highest among the three methods.

- Applicable Scenarios: Scenarios with high requirements for decoration aesthetics, such as villas and high-end offices. Although the maintenance cost is high, it can improve the overall texture of the space and meet the high-end positioning.

7. Comply with Regulatory Standards: Avoiding Risks and Ensuring Safety

While focusing on product performance and cost, regulatory standards should not be ignored. Spring boxes or motors that do not meet the standards may have safety hazards (such as motor overheating and fire, or spring breakage causing the blind body to fall). They may also affect human health due to non-compliance with environmental standards.

7.1 Core Certification Standards and Applicable Scopes

Currently, there are several core certification standards for cordless blind components worldwide, and different standards focus on different testing items:

- EU CE Certification: Focuses on the electrical safety of motors. Testing items include anti-electrical shock protection, insulation resistance, and overheat protection to ensure that the motor does not leak electricity or catch fire during normal use. All motors exported to the EU must pass CE certification. Domestic users can also prioritize products with CE certification when purchasing, as they offer better safety guarantees.

- US ANSI/BHMA A156.26 Standard: Focuses on the lifting system of blinds (including the spring box). It tests the fatigue life of the spring, lifting smoothness, and fixing stability. Spring boxes that pass this standard can ensure a lifting frequency of ≥10,000 times and no sliding of the blind body when stationary.

- China GB/T 29730-2013 Standard: Focuses on the general requirements for building sun-shading products. It covers the environmental protection of materials (such as formaldehyde emission and heavy metal content) and mechanical properties (such as wind load resistance and impact resistance) of spring boxes and motors. Products that meet this standard are suitable for domestic home and commercial scenarios.

- EU REACH Regulation: Focuses on harmful substances in materials. It restricts the content of 197 harmful substances such as lead, mercury, and cadmium. The plastic shell of the spring box and the metal components of the motor must comply with REACH requirements to ensure that no harmful substances are released during use, which is harmless to human health.

When purchasing, you can ask the merchant to provide the product's certification certificate to avoid buying "three-no products" (products without a manufacturer, production date, or quality certificate).

7.2 5-Year Life Cycle Cost Comparison of Spring Boxes and Motors for Medium-Sized Home Blinds

The initial purchase cost of compliant products may be slightly higher, but from the perspective of a 5-year life cycle, they offer better cost-effectiveness. Below, taking the spring box and motor of a medium-sized home blind (width 90cm, height 200cm) as an example, we will compare the 5-year total costs of three options: economical, quality, and intelligent.

Type

Initial Purchase Cost (USD)

Annual Maintenance Cost (USD)

Annual Energy Consumption Cost (USD)

5-Year Total Life Cycle Cost (USD)

Key Description

Economical

21-29

11-17

1-1.4

≈83

Mostly non-compliant products, prone to failures, frequent maintenance

Quality

43-57

4-7

0.7-1.1

≈68

Compliant with CE and GB standards, strong durability, low maintenance cost

Intelligent

71-100

6-9

1.1-1.7

71-100

Compliant with multiple international standards, supports intelligent control, high convenience

It can be seen from the table that the quality type is the most cost-effective choice. Although the initial purchase cost is 22-28 USD higher than that of the economical type, the annual maintenance cost is only 4-7 USD (1/3 of that of the economical type), and the total 5-year cost is 15 USD lower than that of the economical type. This is because quality products comply with regulatory standards, and the materials and craftsmanship of the spring box and motor are of higher quality and more mature, resulting in a low failure rate and no need for frequent maintenance.

Economical products are mostly non-compliant. Their springs are made of inferior steel, and the motors have no overheat protection. They may develop faults after 1-2 years of use, requiring an annual maintenance cost of 11-17 USD, resulting in a higher total 5-year cost. Although intelligent products are convenient, their initial cost is high, making them suitable for users with sufficient budgets who pursue a technological experience, rather than the first choice for the general public.

7.3 The Impact of Warranty Policies

Warranty policies are an "additional guarantee" for compliant products. Products with different warranty periods vary greatly in later maintenance costs. Below, taking motor failure as an example, we will compare the additional expenses for no warranty, 1-year warranty, and 3-year warranty:

- No Warranty: If the motor fails after 2 years of use, you need to bear the replacement cost yourself. The unit price of the motor is approximately 21 USD, and the labor cost is approximately 7 USD, resulting in a total additional expense of ≈29 USD. If the spring box also fails at the same time, the additional expense will be even higher.

- 1-Year Warranty: If the motor fails within 1 year, the manufacturer provides free replacement parts, but you need to bear the labor cost yourself (approximately 7 USD), resulting in a total additional expense of ≈7 USD.

- 3-Year Warranty: If the motor fails within 3 years, the manufacturer not only provides free parts but also covers the on-site labor cost, with no additional expenses.

A family user purchased a quality motor with a 3-year warranty. The motor failed after 2.5 years of use, and the manufacturer arranged for on-site replacement within 2 days without any cost. In contrast, their neighbor purchased an economical motor with no warranty, which failed after 1.5 years of use, and the neighbor had to spend 29 USD on repairs. The advantage of the warranty policy is obvious when comparing the two. Therefore, when purchasing, you need to pay attention to the warranty period and prioritize products with a warranty of ≥2 years, especially for core components such as motors.

8. Innovative Functions of Cordless Blinds: Enhancing Performance and Service Life

With the iteration of technology, cordless blinds are no longer limited to the basic function of "cordless lifting" but have derived a variety of innovative functions. These functions can not only improve the user experience but also extend the service life of the spring box and motor, reducing long-term costs. Below are four innovative functions with high practical value:

8.1 Cordless + Motor Fault Early Warning

Motor failure is one of the most common problems with cordless blinds. Early warning can avoid the inconvenience caused by "sudden shutdown", which is especially suitable for commercial scenarios.

- Function Principle: A current sensor is built into the motor to monitor the current changes of the motor in real-time during operation. When the motor has problems such as aging or bearing wear, the current will fluctuate abnormally (e.g., the current suddenly increases by more than 10%). After detecting the abnormality, the sensor will send an early warning message through the APP or remote control, reminding the user to repair it 7-10 days in advance.

- Applicable Scenarios: Commercial scenarios such as hotels and offices. For example, if the blind motor in a hotel room suddenly fails, it may cause guest complaints. With the early warning function, the hotel can repair it in a timely manner after the guest checks out, avoiding affecting subsequent stays.

- Additional Cost and Benefit: The additional cost increases by 15%-20% (e.g., a regular motor costs 150 yuan, while a motor with an early warning function costs 172-180 yuan), but it can reduce 80% of the losses caused by sudden shutdowns.

8.2 Cordless + Spring Box Self-Repair

A common problem with spring boxes is slight spring deformation, which leads to stuck lifting. If the deformation can be repaired automatically, the maintenance needs can be greatly reduced.

- Function Principle: The spring is made of shape memory alloy, which has the property of "recovering its original shape when the temperature changes". When the spring is slightly deformed due to long-term use, the spring can automatically recover its original shape as long as the ambient temperature changes by 5-10℃ (e.g., the temperature rises during the day and drops at night), eliminating the stuck problem caused by deformation.

- Applicable Scenarios: Home and commercial scenarios with high-frequency use (such as living rooms and offices). In these scenarios, the blinds are lifted 3-5 times a day, and the spring is prone to slight deformation. The self-repair function can avoid frequent disassembly and maintenance.

- Additional Cost and Benefit: The additional cost increases by 10%-15% (e.g., a regular reinforced spring box costs 100 yuan, while one with a self-repair function costs 110-115 yuan), which can reduce 30% of the spring box maintenance needs. A family used a spring box with a self-repair function and only needed to repair it once within 5 years, while a regular spring box needed to be repaired 3 times during the same period, saving approximately 120 yuan in maintenance costs.

8.3 Cordless + Smart Home Linkage

Smart home linkage is a popular function in recent years, which can integrate cordless blinds into the overall smart home system and improve convenience.

- Function Principle: An IoT module is built into the motor, supporting WiFi or Bluetooth connection to link with smart speakers (such as Amazon Echo and Xiaomi Speaker) and mobile APPs. Users can control it through voice commands (e.g., "Open the living room blinds") or remote control via the APP. They can also set scheduled tasks (e.g., "Close the blinds at 18:00 every day") and even link it with a light sensor (the blinds automatically lower when the light intensity >500lux).

- Applicable Scenarios: Young families and technology enthusiasts.

- Additional Cost and Benefit: The additional cost increases by 25%-35% (e.g., a regular intelligent motor costs 200 yuan, while one with a linkage function costs 250-270 yuan), but it can significantly improve the convenience of life. A young family reduced the number of manual blind operations by approximately 50 times per month after using the linkage function, saving a lot of time.

8.4 Cordless + Energy Consumption Self-Adaptation

The energy consumption self-adaptation function optimizes the motor energy consumption, which is suitable for users who use the blinds for a long time and focus on energy conservation, and can further reduce electricity costs.

- Function Principle: The motor has a built-in load detection module that monitors the weight change of the blind body in real-time (e.g., the weight increases due to dust accumulation on the slats) and automatically adjusts the power according to the load. When the load is light (e.g., the blind body weighs 3kg), the power is automatically reduced to 5W; when the load is heavy (e.g., the blind body weighs 6kg), the power is increased to 10W, avoiding energy waste caused by "excessive power when the load is light".

- Applicable Scenarios: Home or commercial scenarios that are used for a long time and focus on energy conservation (such as office buildings). Office buildings have hundreds of blinds, and the energy consumption self-adaptation function can significantly reduce the total energy consumption.

- Additional Cost and Benefit: The additional cost increases by 8%-12% (e.g., a regular DC motor costs 100 yuan, while one with a self-adaptation function costs 108-112 yuan), which is 20%-25% more energy-efficient than a regular cordless motor. An office building equipped 500 blinds with energy consumption self-adaptive motors, saving approximately 1,200 yuan in electricity bills annually, and the additional cost can be recovered within 2-3 years.

9. Eco-Friendly Materials for Cordless Blinds: Balancing Safety and Sustainability

With the improvement of environmental awareness, more and more users pay attention to "material environmental protection" when purchasing. If components such as the spring box shell and motor shell of cordless blinds are made of non-environmentally friendly materials, they may release harmful substances (such as formaldehyde and heavy metals), which affect human health. Environmentally friendly materials are not only safer but also have the advantages of high recyclability and long service life, conforming to the concept of sustainable development. Below is a comparison of the key differences between environmentally friendly materials and ordinary materials:

9.1 Spring Box Shell: Recyclable Plastic vs. Ordinary Plastic

The spring box shell is mostly made of plastic, which is the main plastic component of cordless blinds. Its environmental friendliness directly affects the sustainability of the entire product:

Feature

Recyclable Plastic for Cordless Blinds

Ordinary Plastic for Cordless/Corded Blinds

Recyclability Rate

≥85%

≤30%

Harmful Substance Content

<0.1 mg/m³ (compliant with EU REACH standard)

0.3-0.5 mg/m³

Service Life

5-8 years

2-3 years

Certification Status

EU ECOCERT certification

No environmental certification

9.2 Motor Shell and Spring: Formaldehyde-Free Coated Metal vs. Ordinary Coated Metal

The motor shell and spring are mostly made of metal, and the environmental friendliness of the coating is crucial. Ordinary coatings may contain formaldehyde, while formaldehyde-free coated metals are safer and more durable:

Recyclability: The coating of formaldehyde-free coated metal is tightly bonded to the metal substrate. It can be directly smelted during recycling without peeling off the coating, with a recyclability rate of ≥95%. The coating of ordinary coated metal is easy to fall off. During recycling, the coating must be removed first, which is a complicated process. Although the recyclability rate is ≥80%, it will produce coating waste pollution.

- Formaldehyde Emission: Formaldehyde-free coatings use water-based paints, with a formaldehyde emission of <0.05 mg/m³, which complies with China's Ten-Ring Certification (the highest domestic environmental standard). Ordinary coatings mostly use solvent-based paints, with a formaldehyde emission of 0.1-0.2 mg/m³. During long-term use, formaldehyde will be released slowly, and the emission will increase in high-temperature environments (such as balcony exposure), which may cause respiratory discomfort.

- Service Life: Formaldehyde-free coatings have stronger corrosion resistance. The motor shell will not rust within 8-10 years in a humid environment (such as a bathroom). Ordinary coatings have poor corrosion resistance, and rust will appear after 5-6 years, leading to poor heat dissipation of the motor and shortening its service life.

A user once installed a blind with an ordinary coated metal motor in the bedroom. When the balcony temperature was high in summer, they always felt an unusual smell in the room. After testing, the formaldehyde emission was found to be 0.15 mg/m³. After replacing it with a motor with a formaldehyde-free coating, the smell disappeared, and the formaldehyde test value dropped to 0.03 mg/m³, which was safer and healthier.

10. Common SEO-Optimized Questions about Cordless Blinds (Spring Box and Motor)

10.1 What Size Spring Box is Needed for a 90cm Wide Cordless Blind?

For a 90cm wide cordless blind (taking aluminum material as an example), if the height is 180-240cm, the weight is approximately 4-5kg. According to the selection principle, the load-bearing capacity of the spring box must be ≥ the weight of the blind body, and 30%-50% redundancy should be reserved. Therefore, it is recommended to select a reinforced spring box with a rated load-bearing capacity of 8kg. If it is installed in a bedroom and requires a silent function, a silent reinforced spring box (load-bearing 8kg, operating noise ≤35 decibels) can be selected. If it is installed in a bathroom and requires anti-corrosion function, an anti-corrosion spring box (load-bearing 8kg, waterproof rating IPX4) should be selected. At the same time, attention should be paid to the matching of the spring box interface size with the blind track. The mainstream interface diameter is Φ15mm, and the track interface can be measured in advance when purchasing.

10.2 DC Motor vs. AC Motor: Which is More Suitable for Home Cordless Blinds?

DC motors are preferred for home cordless blinds for three reasons:

1. Low power (5-12W), with an annual power consumption of only about 10kWh and an electricity cost of approximately 6 yuan, resulting in low long-term use costs.

2. No need for municipal power supply; it can be powered by batteries, and no wiring is required during installation, making it suitable for home scenarios where there are no sockets near the windows.

3. Small size and light weight, which can be embedded in the blind cavity without affecting the appearance.

AC motors have high power (15-25W) and require municipal power supply, making them more suitable for large-sized commercial blinds (e.g., width >120cm). If AC motors are selected for home scenarios, problems such as "excessive power" and "high energy consumption" will occur, resulting in low cost-effectiveness.

10.3 How to Reduce the Maintenance Cost of Cordless Blinds in the Bathroom?

Through these three measures, the annual maintenance cost of bathroom blinds can be reduced from 100 yuan to less than 50 yuan.

10.4 Is It Worth Spending Extra on Intelligent Cordless Blinds?

Whether it is worth it depends on the needs:

1. If you are from a young family, a technology enthusiast, or often forget to close the blinds, intelligent cordless blinds (with APP control and scheduled adjustment functions) are worth purchasing. The additional cost is about 25%-35%, but they can bring the convenience of "remote control" and "voice operation" and save time.

2. If you are a tenant, have a limited budget, or have no demand for intelligent functions, ordinary cordless blinds are more cost-effective. The basic lifting function can already meet the needs, and there is no need for extra spending.

From the perspective of long-term costs, the annual energy consumption cost of intelligent motors is only 9.2 yuan, which is slightly different from that of ordinary DC motors. If the budget allows, priority should be given to intelligent models to improve the experience.

10.5 What Certifications Should Eco-Friendly Cordless Blind Components Have?

The core components of eco-friendly cordless blinds need to have the following certifications:

1. Spring box plastic shell: EU ECOCERT certification (recyclability rate ≥85%, harmful substances <0.1mg/m³) and compliance with EU REACH regulation (restricting 197 harmful substances).

2. Motor shell and metal spring: China Ten-Ring Certification (formaldehyde emission <0

Read More