Why Tension Determines Your Blind Experience: A Comprehensive Guide from Traditional to Cordless

Aug 07, 2025

Why Tension Determines Your Blind Experience:

A Comprehensive Guide from Traditional to Cordless

1. What are the spring components for traditional blinds and cordless blinds?

2. Judgment criteria: Make “good/bad” tension quantifiable ?

3. What are the practical methods ? Three-step manual testing + precise measurement tools ?

4. Data insights: 100 sets of measured tension distribution graphs ;

5.What are the common faults ?

6. Adjustment vs. Repair: Adjustable vs. Non-Adjustable ?

7. Preventive maintenance: A 12-month maintenance chart ?

Part 1 Why does “tension” determine your blinds ?

The smooth raising and lowering, stable hovering, and long-lasting durability of Venetian blinds depend heavily on one key factor: tension. Whether in spring assemblies, cord systems, cordless mechanisms, or roller blind designs, imbalanced tension can lead to sticking, loss of security, or premature wear. Yet, most users only notice this problem when their blinds malfunction.

This guide will comprehensively analyze the importance of blind tension from basic knowledge, quantitative standards, practical testing, data insights, fault diagnosis, repair decisions to long-term maintenance, and provide practical solutions covering traditional corded blinds and cordless blinds.

1. Basic cognition: the importance of spring components and tension

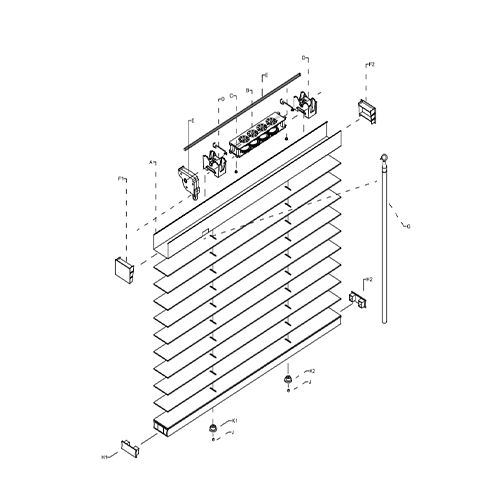

Composition of shutter spring assembly

The spring system of modern blinds is a highly integrated micro-mechanical unit, the core of which is composed of three types of precision components:

(1) Spring body - Depending on the installation space and load requirements, it can be divided into two types: spiral torsion spring and extension spring. Spiral torsion springs are usually made of 65Mn or SUS301 stainless steel. After oil quenching and tempering, the hardness reaches HRC48-52. The surface is then electroplated with environmentally friendly nickel-chromium composite to resist corrosion while maintaining a high elastic limit. Extension springs are mostly formed by cold-rolling music wire with a wire diameter ranging from 0.4-1.2 mm. The loops at both ends are stress-relieved to prevent creep after long-term stretching.

(2) Scroll - As the hub for storing and releasing spring energy, the scroll is made of POM+30% GF engineering plastic injection molding, taking into account both lightweight and wear resistance; a D-shaped hole is provided in the center to fit with the metal core shaft in an interference fit, ensuring coaxiality ≤0.05 mm, thereby reducing radial runout during rotation.

(3) Connectors—consisting of high-strength nylon pulleys, stainless steel pins, and locking washers—are responsible for smoothly transmitting spring torque to the slats while enabling precise tension calibration of ±5 N·cm through preload adjustment washers. These three components work together to form a closed system capable of continuous operation for 30,000 cycles in temperatures ranging from -20°C to 60°C.

Definition of Spring Tension

Spring tension is essentially an elastic restoring force that follows Hooke's law. Its magnitude is proportional to the shear modulus of the spring material, the number of effective turns, the wire diameter, and the torsion angle. In Venetian blinds, tension is quantified as a "balancing torque": at any position in the travel, the rewinding torque provided by the spring must be equal to or slightly greater than the moment of the curtain's weight to ensure that the curtain stops immediately. Expressed in terms of formula, T = k·θ, where k is the torsional stiffness (N·cm/deg) and θ is the torsion angle relative to the initial angle. In design, Tmax is typically set to ≈ 1.15 W·L/2, where W is the total weight of the curtain and L is the extended height. This factor provides a sufficient safety factor while preventing excessive winding.

The necessity of judging tension

(1) Avoid functional failure: Excessive tension will lead to excessive initial pulling force, and the user will need to use a large external force to pull down the curtain. Once released, the curtain will rebound violently under the action of inertia, hitting the top frame and causing noise and structural damage. If the tension is too weak, the curtain cannot overcome the gravity of the curtain, resulting in the curtain being stuck, paused in the middle, or even automatically sliding down. In severe cases, the curtain will fall down without external force, posing a safety hazard.

(2) Extending component life: Coil springs that are in an over-tensioned state for a long time will develop microcracks in the inner grains due to shear stress concentration. The crack propagation rate increases exponentially with the number of cycles, eventually leading to fatigue fracture. Excessive tension causes the weight of the curtain sheet to be mainly borne by the rope or brake, causing these auxiliary components to wear out prematurely. Through regular tension testing (such as using a digital torque wrench to measure the rewinding torque within the standard stroke), re-tensioning or replacement can be performed at the initial stage of crack initiation or wear, and the overall life can be increased from the conventional 20,000 cycles to more than 35,000 cycles.

The following table provides a brief summary for your reference.

The core tension system of a Venetian blind varies depending on the type:

Traditional cord-operated blinds

Components

Function

Effect on tension

Spring Reel

Stores elastic potential energy to balance the weight of blinds

Insufficient tension: Failure to hover; Excessive tension: Rebound too quickly

Draw cord/webbing

Transmits tension to control raising and lowering

Wear or looseness: Operational lag

Clutch mechanism

Adjusts tension distribution (for advanced blinds)

Improper adjustment: Uneven lifting and lowering

Stop

Secures blinds in a specific position (e.g., fully retracted or extended)

Failure: Slats slipping or falling

Cordless blinds

Components

Function

Impact of Tension

Internal balance spring

Replaces pull cords with a spring system for cordless raising and lowering

Insufficient tension: slats droop; excessive tension: difficulty operating

Side rail adjuster

Finely adjusts the balance of the slats

Incorrect adjustment: slats become skewed or stuck

Locking mechanism

Keeps the slats in place

Wear: slats automatically slide

Part 2 What are the judgment criteria ?

Universal standard (applicable to all blinds)

Test Items

Ideal Value

Insufficient tension

Excessive tension

Operational Experience

Light to moderate resistance, smooth rise and fall

Loose, requiring extra force

Stiff, rapid rebound

Hovering Ability

Stable hold at any position for 10 seconds or more

Slipping down or not being able to secure

Rebounds to the top/bottom of the spring

Noise Performance

No sound or slight grinding noise

Rope jittering (traditional)

Spring "clicks"

Cordless Blinds Exclusive Test

1. Push and pull resistance test:

- Gently push the window slats with your fingers. They should move smoothly and stay in place normally. If you need to push harder or the window slats fall back automatically, you need to adjust the side rail tension.

2. “Horizontal Calibration Test”:

- Check that the slats are always level. If one end droops, the spring tension on both sides is uneven.

Part 3. What are the practical methods ? Three-step manual testing + precise measurement tools

1. Traditional cord-operated blinds test

(Same as above)

2. Testing and Adjusting Cordless Blinds

Tool-free manual adjustment:

1. Locate the adjustment holes: usually located on the side of the head rail or inside the end cap.

2. Rotate the adjustment lever:

- Clockwise rotation (+tension) → solves the drooping of the window blades

- Counterclockwise rotation (-tension) → Solve the problem of overtightening

3. Test balance: Repeat the push and pull test until the window blade can hover in any position.

Professional measurement advice:

Using a torque screwdriver , measure the rotation force of the adjustment rod to ensure that the tension on both sides is consistent (reference value: 0.5-1.2 N·m).

Part 4 Data Insights: 100 Sets of Measured Tension Distribution Charts

Data Insights: 100 Measured Tension Distribution Charts (Including Cordless Blinds)

100 sets of measured tension distribution diagrams (including cordless blinds)

Blind Types

Ideal Tension Ratio

Common Problems

Main Causes

Data from AI and website searching ,Refers only.

Traditional Corded Blinds

42%

Loose cord, aging spring

Mechanical wear (over 2 years of use)

Traditional Corded Blinds

58%

Sagging window blades, uneven lifting resistance

Mechanical wear (over 2 years of use)

Part 5 Common Faults of Cordless Blinds

Cordless blinds, thanks to their simple design and child-safety, have become a standard feature in modern homes. However, this cordless design also presents a unique set of problems. The most common complaint is the inability of blinds to maintain their set height. After two to three years of frequent raising and lowering, the spring-loaded balancing system experiences fatigue in the metal coil spring, causing a drop in torque of more than 15%, causing the blind slats to slowly slide down midway. In this case, it's not necessary to completely replace the blind; simply remove the top rail end cap and rewind the spring clockwise half a turn to restore tension. If the coil spring is cracked, it must be replaced with a new one of the same specifications.

The second most common problem is the blinds suddenly "stuck." This is primarily caused by dust and fiber entanglement in the clutch pinion built into the pull cord. To repair, first use a vacuum cleaner with the flat nozzle to remove dust from both ends of the top rail. Then, use a cotton swab dipped in alcohol to clean the white nylon gears. Finally, apply a small amount of silicone-based lubricant. 90% of the stuck cases can be fixed immediately. If the blinds still won't raise or lower, the gear teeth may be chipped and need to be replaced along with the brake cartridge.

Skewed blades are also a user pain point. Cordless blinds rely on a synchro rod inside the bottom rail to keep the blades parallel. If a child pulls on the blades or the curtains are deformed by wind pressure, the plastic connector on the synchro rod can break. In this case, lower all the blinds, gently straighten the skewed blades with pliers, and then measure the length and purchase a connector of the same specification online. It should be reset in ten minutes.

If the louvers slowly rise on their own, it's likely due to worn brake pads. Remove the brake housing, remove the copper brake pads, and lightly sand both sides with 1000-grit sandpaper to remove the glaze. Reinstall the pads to increase friction. If wear exceeds 0.5 mm, replace them.

A common problem with cordless electric chargers powered by lithium batteries is "not charging." First, check if the USB-C port is clogged with lint. Clean it with a toothpick and try again. If the charging indicator still doesn't light up, the battery protection board has likely entered over-discharge sleep mode. Remove the battery pack and use a 5V constant voltage source to wake it up.

Warm reminder: The biggest enemies of cordless blinds are dust and sun exposure. Cleaning the top rails with an electrostatic duster quarterly and lubricating the springs and gears annually can reduce the failure rate by 70%. If self-repairs don't improve the condition, contact us immediately. Avoid violent disassembly, as this will void the warranty.

Added a new fault specific to cordless blinds

Symptom: The window blades cannot remain level

- Root cause:

- Single-sided spring failure (60%)

- Side rail deformation (30%)

- Mounting base tilt (10%)

Symptom: Excessive push and pull resistance

- Root cause:

- Spring too tight (70%)

- Dirt accumulation on guide rails (30%)

Part 6 How to adjust and repair traditional blinds and cordless blinds ?

Traditional Venetian blinds consist of a top rail, ladder cords, and several slats. They are raised and lowered with a lift cord on the right and adjusted with a tilt wand on the left. Cordless blinds eliminate the exposed pull cord and instead utilize a spring or gear system built into the bottom rail for one-handed adjustment. The slat angle is still controlled by a tilt wand or hidden paddles. These structural differences lead to different approaches to use, adjustment, and repair.

A.Daily Adjustments

Traditional blinds: To raise or lower, pull the cord downwards and gently to the side to lock the blind. If the height is not ideal, loosen the cord and then fine-tune it. For angle adjustment, rotate the handle slowly to avoid excessive force that could cause the gears to jump.

Cordless curtains: Hold the center of the bottom rail with both hands and push or pull evenly upward or downward to the desired position. Release your grip and the built-in tensioner will automatically lock. If there is excessive resistance, fully retract the curtain and then re-extend it to reset the spring. Avoid applying force from one side, as this can cause the track to tilt.

B. Common fault self-test

Traditional blinds: broken pull cords, idling rotating rods, and loose ladder belts on one side causing the blades to tilt.

Cordless blinds: cannot stay in position (spring fatigue), track gets stuck (dust accumulation), blades are not level (bottom rail is deformed).

C.Home-level repair

1. Traditional curtains

- Rope replacement: Remove the end cover of the crossbeam, pull out the old rope, and insert the new rope into the original hole. First fix the bottom blade, and then insert the ladder belt upwards in sequence. Be sure to keep the length of the left and right ropes symmetrical. After testing the smooth lifting and lowering, cut off the remaining rope.

- Leveling: If one side of the blade droops, loosen the drawstring first, wrap the corresponding ladder half a circle more and then secure it to restore the level.

- The rotating rod is idling: Open the gear box and check whether the hexagonal shaft is worn. If it is worn, rotate it 180° and continue to use it, or directly replace the plastic gear.

2. Cordless blinds

- Tension reset: lower the curtain completely, use a screwdriver to turn the small tension screw at the end of the bottom rail clockwise half a turn, then raise and lower it repeatedly three times to check whether the positioning is secure; if it still slides down, fine-tune it another half a turn. Do not tighten it too much at one time to avoid over-tightening the spring.

- Clearance: Remove the plugs at both ends of the bottom rail and use compressed air to blow away the fluff and sand. If the rail is still stuck, apply a drop of silicone-based lubricant to the pulley to prevent oil and dust from being absorbed.

- Bottom rail shaping: If it is slightly bent, you can use your hands to straighten it; if it is severely deformed, contact the manufacturer to replace the aluminum alloy rail with the same specification.

D When do you need to contact a professional?

Traditional curtains: cracked crossbeams, broken ladder belts in multiple places, and large areas of blades damaged require the entire curtain to be removed and returned to the factory.

Cordless curtain: The spring assembly is broken, the plastic teeth of the gear box are chipped, the curtain fabric is separated from the rail, and there are no spare parts at home. It is recommended to replace the lifting module as a whole.

E.Preventive maintenance

- Clean both sides of the blades with a soft vacuum cleaner brush every month to reduce the amount of dust that enters the ladder belt and track.

- Before operation, make sure that there is no debris on the windowsill that could obstruct the bottom rail to prevent lateral force.

- A small knot can be tied at the end of the traditional curtain cord to prevent children from pulling it; cordless curtains avoid frequent hovering in the air and reduce spring fatigue.

- Apply silicone grease to the rotating gears and pulleys every spring to keep them smooth and quiet.

With targeted adjustments and timely repairs, traditional blinds can last another ten years. While the cord-free design of cordless blinds reduces the risk of entanglement, it is more dependent on the life of the internal spring. Proper use and periodic tension calibration are key to extending their life.

Part 7 Preventive Maintenance: A 12-month maintenance chart

month Traditional blinds maintenance Cordless Blind Maintenance

1-3 Cleaning the draw cords and rails Check the levelness of the window blades

4-6 Lubricate the spring reel Clean the side rails and make minor adjustments

7-9 Replace worn draw cords Testing push and pull resistance

10-12 Thoroughly check the limiter Calibrate the spring balance on both sides

Cordless vs. Traditional

- Advantages of cordless blinds: No need to pull cords, which is safer and suitable for families with children or pets, but the tension needs to be calibrated regularly to prevent sagging.

- Advantages of traditional blinds: The mechanical structure is highly repairable, but the pull cord system requires more frequent maintenance.

Regardless of which type you choose, proper tension management can extend the life of your blinds by 3-5 years. Use this guide to give your windows the peace of mind they deserve!

Interactive Question: Do you prefer cordless or traditional blinds? What tension issues have you encountered? Share your experiences!

Read More