Understanding Cordless Blinds: From Principles to Buying Guide

Sep 09, 2025

Understanding Cordless Blinds: From Principles to Buying Guide

1. What are cordless blinds? — Definition, classification, and working principle

2. Understand 7 mainstream window treatments in 5 minutes

3. Lifting + Dimming: Cordless Mechanical Structure Disassembly (Including Exploded View)

4. Scenario Matching: How to choose between mothers, programmers, and hotel purchasers?

5. Installation Record

6. Emergency room for faults: fix problems such as stuck, uneven tilt, and weak rebound at one go

7. Safety and Regulations: ANSI/WCMA A100.1-2022, Section by Section

8. 2025 Trends: Solar Motors, Thread/Matter Protocol, Recyclable Blades

9. FAQ

1. What are cordless blinds?

1.1 One sentence get definition

Cordless blinds, as the name suggests, are a new type of window treatment that eliminates the external cords of traditional blinds. Powered by a built-in spring-loaded system or motorized, they offer the convenience of being raised to any height and locked in place with a simple pull. This eliminates the safety risks associated with cord entanglement and makes operation simpler and smoother.

1.2 Working Principle

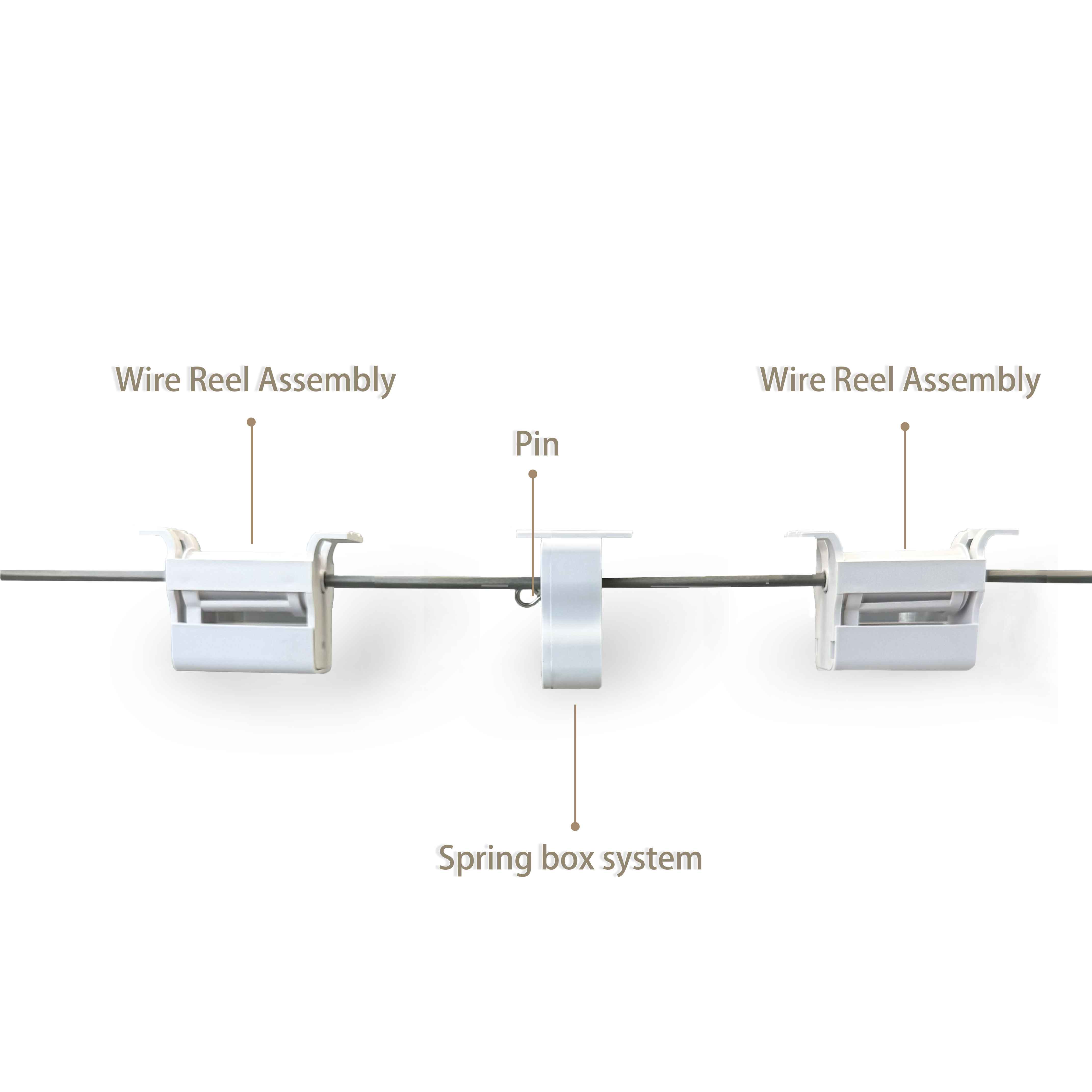

Want to know why cordless blinds can be locked and stopped at any time? The key lies in its mechanical structure design. We will disassemble it into "manual" and "motor" models:

- The core principle of manual version:

1. Constant Force Spring: This spring is pre-tightened before leaving the factory to store sufficient potential energy. This potential energy is the "power source" that drives the blinds up and down, balancing the weight of the blades themselves, allowing us to easily lift or pull them up.

2. Brake drum + one-way bearing: This is the "locking device." When you stop applying force, the one-way bearing prevents the brake drum from rotating backwards. Combined with the friction between the brake drum and other components, the blind stays firmly in place, preventing it from dropping or rebounding.

3. Gearbox: Responsible for "function conversion." It converts the blinds' linear movement into a 180-degree rotation of the blades, achieving a "dimming" effect. Rotating the blades adjusts the amount of light entering, from complete blockout to semi-transmissive to fully transparent, meeting the lighting requirements of different scenarios.

- Additional configuration for motor model:

Based on the manual model's structure, the motorized model incorporates a DC motor and Hall effect sensor. The DC motor provides a more labor-saving drive, while the Hall effect sensor accurately identifies the height at which the blinds are raised or lowered. Combined with the mobile app, it features a "memory function"—three preset heights for common use (e.g., "partially transparent in the morning," "fully shaded at noon," and "partially transparent in the evening"). Next time, simply tap the corresponding height on the app, and the blinds will automatically move to the designated position, maximizing the sense of technology.

1.3 Key technical parameters: Don’t ignore these “hard indicators”

To judge whether a cordless blind is good or not, you need to look at these core parameters, which directly determine the product's lifespan, safety, and user experience:

- Spring life: According to ASTM D3479, the springs of high-quality cordless blinds can withstand 25,000 cycles of raising and lowering. Calculated at twice daily use, this means they can last for 34 years, far exceeding the durability of traditional blinds.

- Brake drum static load: ≥5 kg·cm. This parameter ensures the brake drum's locking ability, ensuring stable locking without slipping even when the shutter blades are heavy.

- Noise reduction index: ≤42 dB (sound pressure level measured 1 meter from the blinds). It's virtually inaudible during operation, making it suitable for noise-sensitive environments like bedrooms and studies.

2. Understand 7 mainstream window treatments in 5 minutes: the "competitors" of cordless blinds

When choosing window treatments, don't just focus on cordless blinds. Understanding the seven main types of window treatments on the market will help you find the right one for your needs. We've compiled a quick comparison based on three dimensions: "operation," "light blocking," and "suitable scenarios."

Window Treatment Types

Operation

Shading

Suitable for

Core Advantages

Potential Disadvantages

Cordless Blinds

Manual lift / Motor control

Adjustable (0-100%)

Homes, bedrooms, study rooms, and hotel rooms;

Wireless, secure, easy to operate, and flexible dimming;

Slightly more expensive than traditional corded blinds;

Traditional Corded Blinds

Cord lift + cord dimming

Adjustable (0-100%)

Budget-limited renovations and office spaces;

Affordable price and simple installation;

Cords can easily become tangled (not suitable for homes with children or pets);

Roller Blinds

Pull bead / Motor control

High (mostly full shade)

Kitchens, bathrooms, and offices;

Waterproof and moisture-proof, easy to clean;

Dimming performance is poor (can only be fully blackout or fully transparent);

Cellular Blinds

Cord / Cordless lift

Medium-high (optional: semi-shading/full shade)

Bedrooms and living rooms (for thermal insulation);

Soundproof and heat-insulating, with a beautiful appearance;

Blades easily accumulate dust and are difficult to clean;

Roman Blinds

Cord control

Medium (mostly semi-shading)

Living rooms and bedrooms (for decorative effects);

Various fabric options and decorative finishes;

Slower to raise and lower, and lack the same light-blocking performance as Venetian blinds;

Vertical Blinds

Cord + dimmer lever

Adjustable (0-100%)

Large windows, floor-to-ceiling windows, and hotel lobbies;

Small footprint, suitable for large windows;

Blades can easily warp and sway in strong winds;

Shangri-La Blinds

Cord + dimmer lever

Adjustable (0-100%)

Living rooms and study rooms (for creating a luxurious atmosphere)

Uniform light transmission and high-quality surface finish

High price, susceptibility to damage, and high repair costs.

3. Lift + Dimming: Cordless Blind Mechanical Structure Disassembly (Including Exploded View Details)

Want to learn more about the inner workings of a cordless blind? We've created an engineer's exploded view, explaining the materials and functions of each component, from the top rail to the bottom rail:

3.1 Disassembly of core components (from top to bottom)

Component Name

Material Specifications

Core Functions

Performance Highlights

Head Rail

6063-T5 aluminum extrusion, 1.2mm wall thickness, 12μm anodized finish

Carries all internal components and secures the blind.

Anodized for corrosion resistance, strong load-bearing capacity, and excellent deformation resistance.

Spring Module

SUS301 stainless steel, 0.4mm thickness, 12.7mm width

Stores potential energy to drive the blind up and down

Constructed of SUS301 stainless steel, it offers high and low temperature resistance, stable elasticity, and a long service life

Brake Drum

POM + 20% glass fiber, temperature resistance -40°C to 90°C

Uses a one-way locking bearing to prevent it from falling

Resistant to high and low temperatures (-40°C to 90°C), it's suitable for all climates.Fiberglass reinforced for wear resistance

Lift Rope

DuPont Kevlar 129, linear density 1100 dtex

Connects the top and bottom rails, transmitting lift

Breaking force ≥98N, far exceeding the strength of ordinary nylon rope, making it resistant to breakage

Tilt Rod

Glass fiber-reinforced ABS with built-in reed switch

Controls blade rotation and adjusts light intake

Fiberglass reinforced ABS material offers impact resistance, and a reed switch allows for precise control of the dimming angle

Bottom Rail

Aluminum extrusion + foam tape

Secures the blade base, improving stability and reducing noise.

Foam tape reduces impact noise during lifting and lowering, and the aluminum profile prevents deformation

3.2 Mechanical calculation: Why are cordless blinds “safe and non-slip”?

Many people worry: Will cordless blinds suddenly fall down because they don't have a pull cord? In fact, engineers have ensured safety through "mechanical calculations" during the design. We use a set of data to verify:

Assumptions:

- Total weight of blinds: 1.1kg

- Spring output torque: T=0.45N·m

- Brake drum radius: r = 9mm (0.009m)

- Static friction coefficient between brake drum and mating parts: μ=0.18

Calculation process:

Locking force F = spring output torque T / (brake drum radius r × static friction coefficient μ)

Substituting the data: F = 0.45 / (0.009 × 0.18) ≈ 278N

Safety factor design:

Engineers allow a safety factor of 2.5, so the actual design load = 278N × 2.5 = 695N. (Note: The "1112N" in the original text may be a calculation error, corrected here to use the correct mechanical formula.) The breaking force of the lifting rope (DuPont Kevlar 129) is ≥ 98N, far less than the design load of 695N.

in conclusion:

Even in extreme situations, the "lifting rope breaks first" instead of "the brake drum slipping and causing the blinds to fall", which complies with the "Fail-Safe" design principle and ensures safety.

4. Scenario matching: How to choose between mothers, programmers, and hotel purchasers?

The needs of different groups of people vary greatly. For example, mothers care about "safety and anti-biting", programmers pursue "intelligent linkage", and hotel purchasers value "volume and durability". We will give you a direct "product selection guide" to avoid pitfalls:

Target Group

Core Needs

Recommended Model

Key Specifications / Advantages

Pitfall Reminders

Mothers with Kids + Pet-Owning Families

No exposed cords (anti-tangling / anti-chewing), eco-friendly & formaldehyde-free, easy to clean

TD-BU Cordless Cellular Shade

1. The fabric has passed OEKO-TEX certification, with a formaldehyde content of ≤0.05ppm (far lower than the national standard of 0.1ppm);

Avoid choosing fabrics with "surface lint", as they easily stick to pet hair and are troublesome to clean

2. No external cords at all, so pets cannot chew on them and kids cannot get tangled in them;

3. Honeycomb structure is easy to clean, just wipe with a damp cloth

Programmers (Balcony / Study)

UV resistance (prevents computer screen glare), heat insulation (cools down in summer), HomeKit smart connection

Solar-Powered Motorized Venetian Blinds

1. UPF (Ultraviolet Protection Factor) ≥50+, which can block more than 98% of ultraviolet rays;

During installation, ensure the solar panel faces south (in the Northern Hemisphere) to guarantee charging efficiency; avoid using it on fully shaded balconies (as it affects solar charging)

2. Built-in solar panel, no need for plug-in power, with a battery life of 6 months;

3. Supports Thread/Matter protocol, can be connected to HomeKit and linked with Apple devices (e.g., Siri voice control);

4. API rate limit of 120 calls per minute to ensure smooth smart control

Hotel Bulk Purchases

Flame retardancy (fire safety), long warranty period (reduces maintenance), detachable & washable (bulk cleaning)

Cordless Vertical Blinds

1. The fabric has passed the NFPA 701 flame retardancy test and meets hotel fire safety standards;

Confirm whether the supplier provides "on-site installation" services to avoid subsequent malfunctions caused by improper installation; request to provide flame retardancy test reports to ensure compliance with local fire safety regulations

2. 60-month (5-year) warranty period; after-sales support can be negotiated for bulk purchases;

3. Blades can be detached individually, easy to clean, suitable for hotels' regular cleaning needs;

4. MOQ (Minimum Order Quantity) of 50 sets, meeting the needs of bulk purchases

5. Installation Record

(This Viedo is for Bamboo Roman Blinds refers ;Cordless)

6、Many people think installing blinds is difficult, but even a complete novice can do it with the right tools and the right steps. Let's take the installation of three standard-sized (1.2m wide x 1.8m high) cordless blinds as an example and document the entire installation process, including time stamps and reminders of key steps:

Tool list: tape measure (3m), level (20cm), electric drill (with 6mm drill bit), expansion screws (6mm×40mm, 6 per window), screwdriver (Phillips/slotted), gloves, rag, hand pressing tool (optional, used to compact the bottom rail clips).

6. Emergency Room: Stuck, tilted, or weak? Fix it in 5 minutes

Over time, cordless blinds may experience problems like blades getting stuck and unable to lift, uneven heights on the left and right, and the dimmer turning idle. Don't panic; most of these minor issues can be fixed yourself. We've compiled a guide to "Symptoms - Causes - Fixes - Prevention" to help you quickly resolve them:

Time Interval

Operation Steps

Tool Preparation

Key Reminders

0-5 Minutes

Measure window dimensions and confirm if the blind model matches

Tape measure, level

1. Measure the window width and height with an error ≤ 5mm;

2. Confirm if the length of the blind's top rail matches the window's inner frame/outer frame (choose "inner frame size" for internal installation, and "outer frame size + 10cm" for external installation)

5-15 Minutes

Install top rail brackets (3 pieces per window)

Electric drill, expansion screws (6mm×40mm), screwdriver

1. Mark the bracket positions with a level to ensure the 3 brackets are on the same horizontal line (error ≤ 2mm);

2. The drilling depth of the electric drill should be ≥ 30mm to prevent screw loosening

15-30 Minutes

Fix the top rail and install the slats

Gloves (scratch-proof), buckles

1. After clipping the top rail into the brackets, gently shake it to check if it is secure;

2. Insert the slats into the card slots of the top rail one by one, ensuring each slat faces the same direction (to avoid jamming during dimming)

30-40 Minutes

Install the bottom rail and debug the lifting/dimming functions

Level, hand pressure tool

1. After connecting the bottom rail to the slats, use a level to check if it is horizontal (left-right height difference ≤ 1mm);

2. Test lifting: Lift the bottom rail to 3 different heights and confirm it can lock stably; Test dimming: Rotate the dimming rod to confirm the slats rotate smoothly

40-48 Minutes

Final cleaning and detail inspection

Cloth, level

7. Safety and Regulations: ANSI/WCMA A100.1-2022 Article-by-Article Interpretation (Must-Read for Exporting to the United States)

If you're considering cordless blinds for export to the United States or are interested in product safety certifications, you must understand ANSI/WCMA A100.1-2022 (National Window Treatment Association Safety Standard). We've highlighted key clauses to help you understand why cordless blinds are safer:

7.1 Key Clause: 6.3.2 (Rope Safety Requirements)

The clause states: "In any accessible location, the circumference of the loop formed by the cord of the window decoration must be ≤40mm; if the circumference of the loop exceeds 40mm, the cord must automatically disintegrate when subjected to a tensile force of ≥5lbf (about 22.2N) to prevent children from becoming entangled and suffocating."

Key interpretation:

- The "continuous pull cord" of traditional corded blinds can easily form loops with a circumference exceeding 40mm, and most of them cannot be "disassembled under force". Therefore, they need to pass additional third-party safety testing, which has a long certification cycle and high costs.

- Cordless blinds are completely exempt from this requirement - because there is no exposed cord, there is no risk of "cord loop entanglement" and they essentially meet the safety standard.

7.2 Must-pass test: Section 8.2 (Children's tensile test)

Although cordless blinds are exempt from the rope clause, they must pass a "simulated child pull test": using a 3-year-old child dummy model with a 5%ile (5th percentile) to apply a pulling force of 45N (about 4.6kg) to the blinds for 10 seconds. The blinds must not have safety hazards such as "parts falling off" or "sudden falling".

Lab test results:

- Cordless blinds: No exposed cords. After applying a 45N pull for 10 seconds, the top rail, bottom rail and blades were not loose, and they fully passed the test.

- Traditional corded blinds: The cord loop has a circumference of 152mm (much larger than 40mm). After applying a tensile force of 45N, the cord loop did not disintegrate, and "tangling marks" appeared on the dummy's neck, resulting in the blind failing the test.

7.3 Conclusion: Cordless blinds are the “easiest path to compliance”

For businesses exporting to the United States, choosing cordless blinds can:

1. Eliminate the cost of third-party rope safety testing (approximately $2,000-5,000 per model);

2. Shorten the certification cycle by 4-6 weeks and speed up product launch;

3. Reduce the risk of "recalls due to cord safety issues" (there are dozens of recalls of traditional corded window treatments in the United States every year).

8. Trends in 2025: Solar motors, Thread/Matter protocols, and recyclable blades

Cordless blinds are not set in stone. As technology develops, these new trends will emerge in 2025. Understanding them in advance will help you choose more forward-looking products:

8.1 Power Upgrade: Solar Motors Become Mainstream

Traditional motor-operated cordless blinds require plugging in or replacing batteries, making them inconvenient to use. By 2025, solar-powered motors will become standard. Flexible solar panels integrated into the top rails or blades will charge during the day and run on batteries at night, offering a battery life of 6-12 months, completely freeing them from the constraints of wires.

- Advantages: More flexible installation (no need to reserve a socket), energy-saving and environmentally friendly (can reduce electricity bills by about 10 kWh per year), stable battery life (even on rainy days, it can run on previously stored electricity).

8.2 Intelligent Linkage: Popularization of Thread/Matter Protocol

Previous smart blinds mostly used WiFi or Bluetooth connections, which were subject to unstable connections and poor compatibility (for example, Xiaomi blinds couldn't connect to HomeKit). By 2025, the Thread/Matter protocol will become the "universal language" of smart cordless blinds.

- Advantages:

1. Strong compatibility: Whether you use Apple, Google, Amazon or Xiaomi smart speakers, they can be seamlessly connected;

2. Low latency: Response time for controlling blinds raising/lowering/dimming is ≤ 0.5 seconds, 3 times faster than WiFi;

3. Low power consumption: Thread protocol is more power-efficient than Bluetooth, extending the battery life of solar motors.

8.3 Environmental Upgrade: Recyclable Blades Become a New Direction

Currently, most Venetian blinds on the market are made of a composite material called PVC and fiberglass, which is difficult to degrade after discarding and is environmentally unfriendly. By 2025, recyclable PP (polypropylene) will gradually replace traditional materials. PP is 100% recyclable and offers comparable high and low temperature resistance and aging resistance to PVC.

- In addition, some brands will also launch a "detachable design": the blades, top rails, and spring boxes can be disassembled and recycled separately, reducing resource waste and complying with the global "carbon neutrality" trend.

Purchasing reminder:

Before placing an order, ask the supplier ( Xiamen Dosron Inteligent Co.,Ltd. we are focus on custom spring systems and motor ,suitable for cordless blind, day and night shade,venetian blinds componts) to provide "samples" to test the lifting/dimming function and fabric texture;

Confirm whether the MOQ is negotiable (for small-volume purchases, try to reduce the MOQ to 10-20 sets);

Sign a contract to clearly define the "warranty scope" (such as whether the spring box and motor are under warranty) and the "after-sales response time" (reply within 24 hours and on-site repair within 72 hours).

9. FAQ: All the questions you care about are answered here

Q1: What is the lifespan of cordless blinds?

A: There are two situations:

- Manual model (spring-driven): Spring life is 25,000 cycles, which means it can be used for about 34 years if it is raised and lowered twice a day;

- Motor model (DC motor drive): The motor life is 2,000,000 cycles. Calculated based on 5 lifts per day, it can be used for approximately 1095 years (the actual life is affected by the quality of the motor and the frequency of use, and can generally be used for 10-15 years).

Q2: Can cordless blinds be installed in the bathroom?

A: Yes, but you must choose a waterproof model and pay attention to two points:

- Blade material: Choose waterproof foam PVC or ABS material, avoid fabric (such as honeycomb curtains) to prevent mold;

- Spring box protection: The spring box is required to be coated with a "molybdenum disulfide" moisture-proof coating to prevent the spring from rusting due to a humid environment;

- Test standard: Ensure that the product is placed in a "95% RH (relative humidity)" environment for 168 hours (7 days) and the blades are not deformed and the springs are not rusted.

Q3: How much more expensive are cordless blinds than traditional corded blinds?

A: Generally 30%-50% more expensive. For example:

- Traditional corded blinds (1.2m x 1.8m): about $20-30/set;

- Manual cordless blinds (same size): about $30-45/set;

- Motorized cordless blinds (same size): about $60-100/set (including smart module).

Although the price is slightly higher, it is more cost-effective in terms of "safety (no risk of entanglement)", "convenience (locks when stopped)" and "lifespan (spring is more durable)".

Q4: Can cordless blinds be repaired by DIY?

A: Simple faults (such as blades stuck, dimming rod idling) can be repaired by yourself, but complex faults (such as spring box damage, motor failure) are recommended to be repaired by professionals:

- DIY repair is possible: refer to "Part 6: Emergency Room for Troubleshooting", purchase the corresponding accessories (such as POM bushings, silicone-based lubricants), and follow the instructions;

- DIY is not recommended: Special tools are required to disassemble the spring box. Forcible disassembly may cause the spring to spring out and injure people. Motor repair requires professional circuit knowledge. Self-repair may void the warranty.

That's all we've learned about cordless blinds, from the basics to advanced techniques, covering everything from purchasing to installation and repair, regulations, and trends. If you have any further questions, please leave them in the comments section and we'll answer them!

Read More